Comparison of Properties Between Synthetic Diamond and Synthetic Sapphire

Comparison of Properties Between Synthetic Diamond1 and Synthetic Sapphire2

| Dimension | Synthetic Diamond (CVD/HPHT) | Synthetic Sapphire (Al2O3, Flame Fusion/Czochralski/Edge-Defined Film-Fed Growth, etc.) |

|---|---|---|

| Material & Structure | Elemental carbon, cubic diamond structure; intrinsic insulator, can form p-type (boron-doped) and high-energy irradiation/doped n-type | Aluminum oxide crystal, trigonal crystal system (corundum structure); insulator |

| Crystal Properties | Optically isotropic (homogeneous) | Optically anisotropic (uniaxial, negative optical sign) |

| Hardness & Wear Resistance | Mohs hardness 10; microhardness ~10060 kgf/mm²; wear resistance ~40–200× that of cemented carbide, 2000–5000× that of heat-treated steel/high-speed steel, 90× that of corundum | Mohs hardness 9, second only to diamond |

| Density | ~3.52 g/cm³ | ~4.00 g/cm³ |

| Thermal Properties | Room-temperature thermal conductivity ~2000 W·m⁻¹·K⁻¹; begins oxidizing at ~720℃; graphitization occurs ~1500℃ in inert atmosphere | Melting point ~2050℃, maximum working temperature ~1900℃; thermal conductivity significantly lower than diamond |

| Optical Windows | Broadband high transparency (X-ray to microwave), suitable for high-power windows/lenses | High transparency in visible and near-infrared, commonly used for visible–NIR windows and optical components |

| Electrical & Semiconductor | Intrinsically high resistivity; doping enables p-type (boron) and high-energy irradiation/doped n-type; bandgap ~5.5 eV | Primarily used for insulation/dielectric purposes; not mainstream semiconductor substrate |

| Chemical & Radiation Resistance | Stable against most acids/bases at room temperature; requires protection against high-temperature oxidation | Extremely strong chemical stability; only eroded by HF, hot phosphoric acid, molten KOH, etc., at high temperatures |

| Growth & Size | CVD single crystals can grow to inch scale and be processed; HPHT also usable for gemstone/device-grade | Industrially mature, with 85 kg-class and larger single crystals achievable |

| Cost & Consistency | High-grade single crystals and functional device-level materials costly, constrained by defect density and thermal design | Highly mature processes/industry, relatively more controllable cost and consistency |

Summary: Diamond exhibits high chemical stability at room temperature but begins oxidizing in air at ~720℃ and graphitizes at ~1500℃ in inert atmospheres, necessitating thermal designs to avoid high-temperature oxidation. Its high thermal conductivity and insulation make it suitable for high-heat-flux device cooling and high-power microwave/optical windows. Sapphire remains stable in high-temperature and highly corrosive environments but has lower thermal conductivity, making it more suitable for medium-to-high-heat-flux applications prioritizing optical/chemical stability in windows and substrates.

-

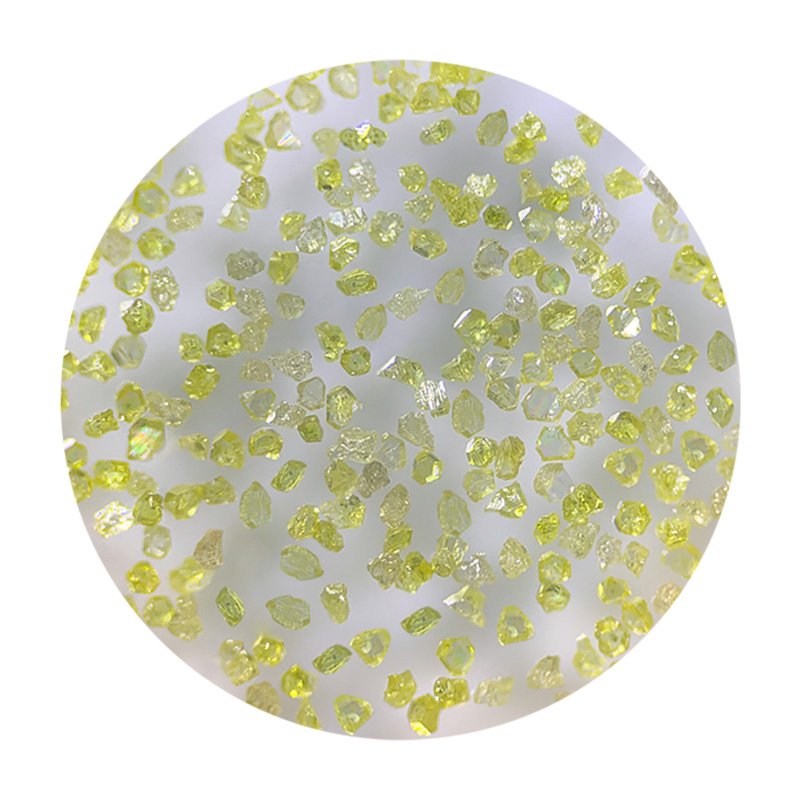

Explore the unique properties of Synthetic Diamond to understand its applications and advantages over natural diamonds. ↩

-

Discover the characteristics of Synthetic Sapphire, which can help you appreciate its uses in various industries.

Comparison of Properties Between Synthetic Diamond and Synthetic Sapphire ↩