How do we make a sapphire window?

Struggling with materials that can't handle extreme conditions? Standard glass fails under pressure, heat, and abrasion. We manufacture sapphire windows that solve these problems with superior durability and clarity.

The best way to make a sapphire window is by growing a large, single crystal of synthetic sapphire, slicing it into wafers with a diamond saw, and then meticulously grinding and polishing those wafers to achieve the desired thickness, flatness, and optical transparency. It is a multi-stage, precision-controlled process.

The journey from a simple white powder to a perfectly clear, incredibly hard window is fascinating. It's a process that my team at Wanbao Technology has perfected over many years. It's not like making regular glass at all. It's a combination of high-temperature chemistry and precision engineering. Many people are surprised to learn that the "glass" in a high-end watch isn't glass at all, but a testament to this advanced manufacturing. Let's explore exactly how we turn a raw material into one of the toughest transparent materials known to man.

How do they make a sapphire glass?

Have you ever wondered what "sapphire glass" really means? The name is a bit misleading. It sounds delicate, but it's one of the toughest materials out there.

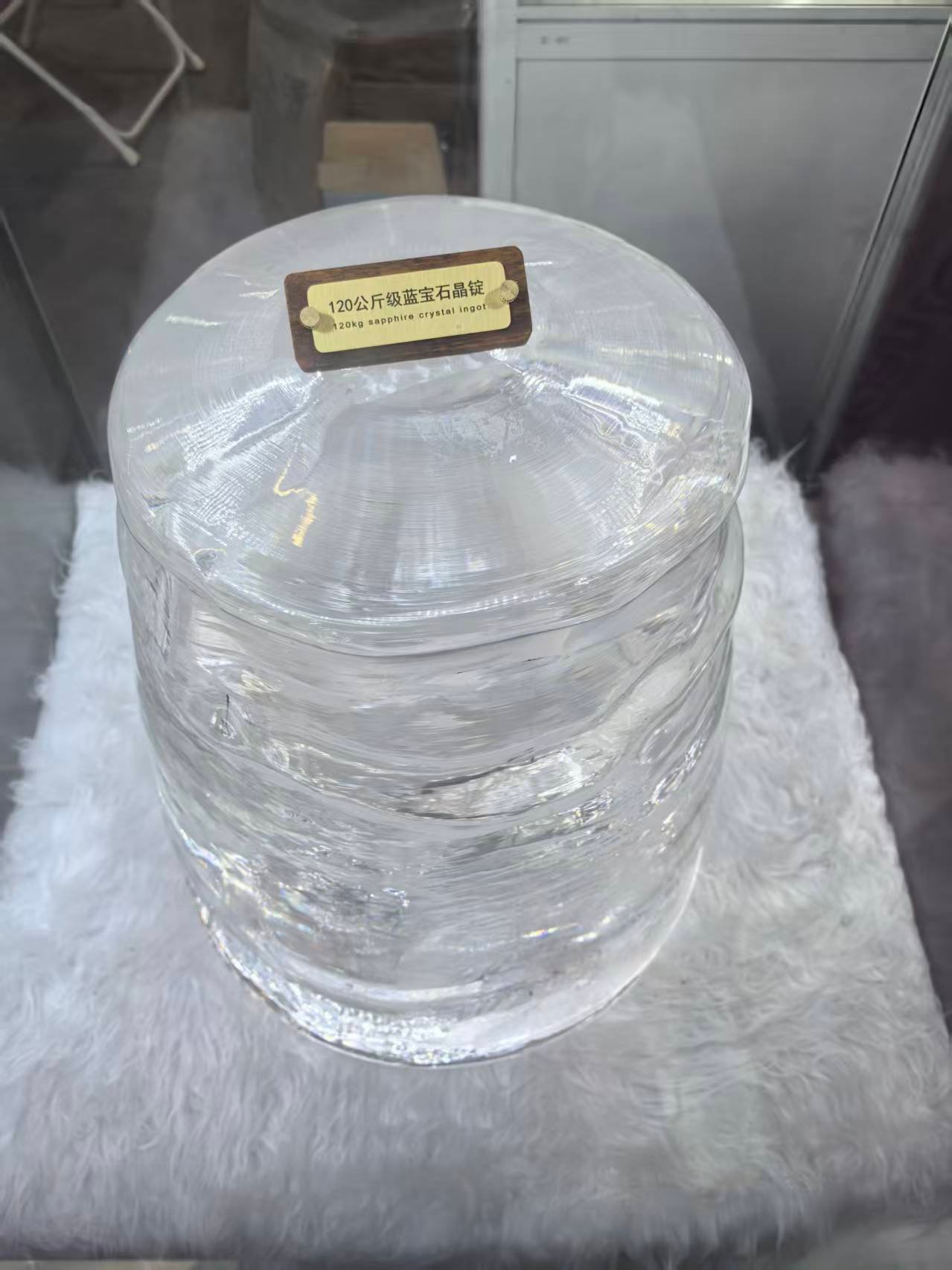

Sapphire glass is not glass. It is a man-made, single-crystal sapphire created by melting high-purity aluminum oxide powder at over 2000°C. This large crystal, called a boule, is then cut and polished to create a transparent component that looks like glass but is much stronger.

The process of creating sapphire components is something we take great pride in at my company. It requires a level of expertise that few possess, not just in China but globally. It all begins with a raw material and ends with a component of incredible strength and clarity. Based on my experience, the journey can be broken down into two main stages: growing the crystal and then shaping it.

Stage One: Crystal Growth

The foundation of any sapphire window is the crystal itself. We start with very pure aluminum oxide (Al₂O₃) powder. This powder is placed in a special furnace. We heat it to an extremely high temperature, well over 2,000 degrees Celsius, until it melts into a liquid. Then, a tiny seed crystal of sapphire is introduced. By very slowly and precisely lowering the temperature over many days or even weeks, the molten alumina crystallizes around the seed, growing into a large, single crystal cylinder called a "boule." This process requires immense energy and control. Any impurity or temperature fluctuation can ruin the entire batch, which is why the equipment and technical skill involved are so advanced.

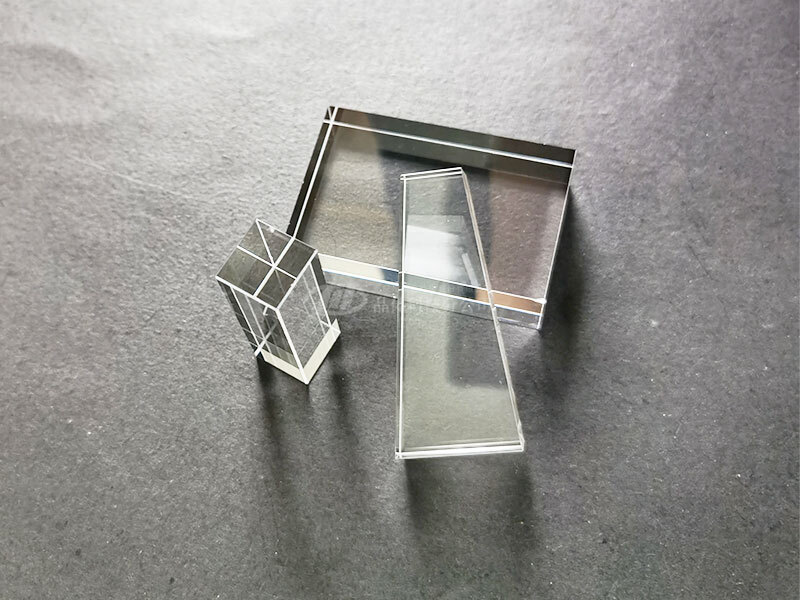

Stage Two: Machining and Polishing

Once we have a solid sapphire boule, the real work of shaping it begins. This is where the extreme hardness of sapphire presents a major challenge. It's the second hardest natural material after diamond. We use saws with diamond-embedded wires to carefully slice the boule into wafers of a specific thickness. These rough-cut wafers are then moved to lapping machines. Lapping involves grinding the surfaces with diamond abrasives to make them perfectly flat and parallel. Finally, the wafers go through a multi-step polishing process, using finer and finer diamond pastes until the surfaces are perfectly smooth and optically clear. Each step is slow and demands precision, which is why experienced technicians are essential.

Is sapphire glass costly?

Are you considering sapphire for a project but are concerned about the budget? The price can seem high at first glance. But understanding the reasons for the cost reveals its true value.

Yes, sapphire is much more expensive than traditional glass. Its high cost is a direct result of the energy-intensive crystal growth process, the slow and difficult machining required due to its hardness, and the expensive diamond tooling needed to cut and polish it effectively.

In my line of work, the question of cost comes up all the time. Customers need to justify the investment. When I explain the process, the value becomes clear. It's not an overpriced material; it's a high-performance one whose price reflects the incredible effort needed to produce it. The cost isn't just about the raw material. It’s about energy, time, and the specialized tools we have to use. There’s a world of difference between manufacturing a simple glass pane and a precision sapphire window.

The Cost of Energy and Time

The initial crystal growth is a major cost driver. Our furnaces must maintain temperatures above 2,000°C for weeks at a time to grow a single, large boule. The amount of electricity consumed is enormous. This isn't a quick process you can do in an afternoon. It's a long, continuous, and energy-intensive operation. Furthermore, the machining that follows is deliberately slow. Rushing the cutting or polishing of such a hard material would cause fractures and defects, wasting the entire expensive piece. So, the long cycle times for both growth and machining add significant cost in terms of energy, labor, and machine hours.

The Cost of Tooling and Expertise

Because sapphire is so hard, ordinary tools can't even scratch it. We must use tools made from the only material that is harder: diamond. Diamond-wire saws, diamond grinding wheels, and diamond polishing slurries are all standard in our facility. These tools are much more expensive than their conventional counterparts and they wear out, requiring frequent replacement. Below is a simple table to show the difference.

| Feature | Standard Glass | Synthetic Sapphire |

|---|---|---|

| Raw Material | Inexpensive (Silica) | Moderate (High-purity Alumina) |

| Energy Input | Low | Extremely High (Crystal Growth) |

| Machining Tools | Standard Steel/Carbide | Expensive (Diamond) |

| Processing Time | Fast | Very Slow |

| Overall Cost | Low | High |

This table simplifies it, but it shows why the investment is higher. You are paying for a material that can withstand conditions that would instantly destroy glass.

How to make sapphire for screens?

We see "sapphire screen" on premium devices like watches and smartphones. Have you wondered how they make it so thin and perfectly clear, yet incredibly scratch-resistant?

To make sapphire for screens, a large synthetic sapphire crystal is grown. It is then oriented and sliced into very thin wafers, often under 1mm thick. These wafers are precision ground for uniform thickness and then polished to optical clarity before being cut into screen shapes.

Making sapphire for a screen is a specialized version of making a sapphire window. The principles are the same, but the tolerances are even tighter. At Wanbao Technology, we have produced thousands of custom sapphire components, and the challenge with screen applications is always achieving that perfect balance of thinness and strength. I remember when we first started developing ultra-thin wafers; our initial scrap rate was high. It took our engineers a lot of trial and error to perfect the lapping and polishing techniques to get consistent results without causing micro-fractures in the material.

From Wafer to Ultra-Thin Sheet

The process starts with a high-quality sapphire boule. The orientation in which we slice the crystal is critical because it affects the final strength of the screen. After slicing the boule into wafers, the next step is thinning. This is done through a process called lapping, where the wafers are ground between two large rotating plates with a diamond slurry in between. We have to remove material with micrometer precision to achieve a uniform thickness of, say, 0.6mm across the entire wafer. If the pressure is uneven or the process is too fast, the thin wafer can easily shatter. It's a delicate, high-stakes operation that relies heavily on advanced machinery and the feel of an experienced operator.

Achieving Optical Perfection

After the wafer is thinned, its surface is frosted and opaque. It's not ready to be a screen yet. The next stage is extensive polishing. This is a multi-step process where we use progressively finer diamond pastes to smooth the surface until it becomes perfectly transparent. The goal is to eliminate any surface scratches or haze that would distort the light from the display underneath. After polishing, the large, thin wafer is cut into the final shapes for individual screens using a laser or another diamond tool. For some applications, we also add final touches like anti-reflective coatings to reduce glare or oleophobic coatings to resist fingerprints. Every step is about adding value and functionality to this incredible material.

Conclusion

Making a sapphire window is a complex, high-tech process. It involves growing a crystal, then using diamond tools for precise cutting and polishing to achieve unmatched durability and clarity.