What is synthetic sapphire?

What is synthetic sapphire?

You hear the word "synthetic" and might think of something fake or inferior. This common misunderstanding can stop you from choosing a superior material. We make a material that solves this.

Synthetic sapphire is a man-made crystal, not a type of glass. It is physically and chemically identical to natural sapphire gemstone. We create it in a lab to achieve near-perfect purity and large, usable sizes for demanding industrial and technological applications.

At my company, Wanbao Technology, we specialize in turning these incredible crystals into precision components. It's a field that requires immense technical skill. There are not many companies in China, or even worldwide, that can machine this material to the tolerances our customers need. The process is challenging, but the result is a material with properties that open up new possibilities in technology and industry. People often ask me what it is and how it's different from the gems in jewelry. Let's look into that.

What is the difference between synthetic sapphire and natural sapphire?

Are you wondering if lab-grown sapphire is "real"? This confusion is common. Understanding the key differences will help you see why one is perfect for jewelry and the other for technology.

The main differences are origin, purity, and cost. Natural sapphire forms in the earth and has flaws. Synthetic sapphire is grown in a lab, making it virtually flawless and available in large, consistent shapes. This control makes it better for technical uses.

I've had many conversations with clients who were initially hesitant about using a "synthetic" material. They associate it with being a cheap imitation. But for engineering, the opposite is true. The "flaws" and "inclusions" that can give a natural gemstone character are weaknesses in a technical component. A tiny impurity can cause a failure under pressure or high heat. Our lab-grown process eliminates these variables. We provide a material you can rely on completely.

Here’s a breakdown of the key differences:

Origin and Purity

Natural sapphire is a mineral, corundum, that forms deep within the Earth's crust over millions of years. It often contains trace elements like iron and titanium, which give it its famous blue color, but also other impurities and structural flaws. Synthetic sapphire is also corundum, but we grow it from high-purity aluminum oxide in a controlled environment. This process removes almost all impurities, resulting in a crystal that is over 99.99% pure. This purity is what makes it perfectly transparent and incredibly strong.

Size, Shape, and Cost

Natural sapphires are found as irregular crystals and are priced based on their rarity, color, and clarity (the 4Cs). Large, flawless natural gems are exceptionally rare and expensive. In our labs, we can grow large, uniform boules (cylinders of crystal) that can be more than 300mm in diameter. We can then cut and shape this material into windows, rods, tubes, and lenses with high precision. While the process is energy-intensive and costly, it is far more predictable and affordable than trying to find and shape a giant, flawless natural sapphire for industrial use.

| Feature | Natural Sapphire | Synthetic Sapphire |

|---|---|---|

| Origin | Mined from the Earth | Grown in a laboratory |

| Purity | Contains impurities, inclusions | Over 99.99% pure Al₂O₃ |

| Form | Irregular crystals | Large, uniform boules/shapes |

| Use | Primarily jewelry | Industrial, medical, optical |

| Cost | High, based on rarity | High, based on manufacturing |

What are the characteristics of artificial sapphires?

Do you need a material that simply will not fail? Glass shatters, plastic scratches, and metal corrodes. When standard materials are not good enough, you need to look for something better.

Artificial sapphire has exceptional characteristics. It is extremely hard, second only to diamond. It is also highly resistant to heat and chemicals, and it is transparent to a wide range of light, from ultraviolet (UV) to mid-infrared (IR).

The unique combination of properties is why my team and I work with this material every day. It solves problems that other materials can't touch. We make parts for industries that push the limits of science and engineering. For them, sapphire isn't a luxury; it's a necessity. Its incredible resilience comes from its fundamental structure as a single, perfect crystal. Let’s break down its most important features.

Extreme Hardness

On the Mohs scale of mineral hardness, sapphire scores a 9 out of 10. The only natural material harder is diamond, which is a 10. This means it is virtually scratch-proof. You can try to scratch a sapphire window with steel, sand, or keys, and it will remain perfectly clear. This is why it’s the preferred material for high-end watch faces, barcode scanner windows, and the protective covers on smartphone cameras. It maintains its clarity even in very abrasive environments.

Chemical and Thermal Stability

Sapphire is chemically inert. It does not react with strong acids or alkalis, even at high temperatures. This makes it perfect for use as viewports in chemical reactors or as components in medical devices that must undergo harsh sterilization processes. Furthermore, it has a very high melting point of 2040°C and maintains its strength at temperatures where most metals would weaken and glass would melt. This thermal stability is critical for applications in furnaces, aerospace, and high-power laser systems.

Broad Optical Transmission

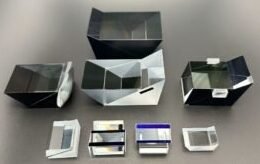

Unlike most types of glass, which only transmit visible light, sapphire is transparent across a very wide spectrum. It lets light through from deep ultraviolet (UV), through the entire visible spectrum, and into the mid-infrared (IR) range. This wide transmission window makes it an essential material for scientific and optical instruments. We manufacture sapphire lenses, prisms, and windows for UV sterilization equipment, IR sensors, and a wide variety of research applications.

What are synthetic sapphires used for?

Do you have a design problem where no standard material seems to work? You might be overlooking a powerful solution. Synthetic sapphire is a key component in many of today's most advanced technologies.

Synthetic sapphires are used anywhere extreme durability, chemical resistance, and optical clarity are needed. Key uses include scratch-proof screens, camera lenses, medical endoscopes, semiconductor processing equipment, and high-pressure windows for industrial machinery.

The list of applications for our products at Wanbao Technology is huge. We have supplied over 3,800 different types of sapphire components over the years. This experience has shown me just how versatile this material is. Its unique characteristics solve critical problems across many different fields. The difficulty of machining it means that each application requires a specialized approach, something my team has perfected over decades.

In Optics and Electronics

Because it is so scratch-resistant and clear, sapphire is the top choice for protecting sensitive electronics. This includes watch faces, smartphone screens, and camera lenses. Its broad optical transmission also makes it essential for more specialized optics. We produce sapphire optical guides and lenses for fiber optic communication and scientific research instruments that need to see in the UV or IR spectrum. In the semiconductor industry, its purity and durability make it the ideal material for wafers and handling tools used in manufacturing computer chips.

In Industrial and Scientific Fields

In heavy industry, conditions can be brutal. We manufacture sapphire high-pressure water jet nozzles that can cut steel, and they last much longer than metal nozzles. We also make sapphire windows and tubes for viewing inside high-temperature furnaces or high-pressure chemical reactors. Its strength and chemical inertness provide a safe and clear view where glass would fail. Its hardness also makes it perfect for precision measurement tools, like the ruby measuring needles and jewel bearings we produce.

In Medical Devices

The medical field relies on materials that are biocompatible and can withstand repeated sterilization. Sapphire is perfect for this. It is used to make the lenses on the tips of endoscopes, giving surgeons a clear, durable view inside the body. It's also used for surgical guides, blades, and even some types of implants because it is strong and the human body does not react to it. We produce sapphire one-way valves and plunger rods for medical pumps that handle aggressive fluids with extreme precision.

Conclusion

Synthetic sapphire is a lab-grown crystal with the same properties as a natural gem. Its superior hardness, clarity, and resistance make it essential for advanced technology and industry.